Advanced Li ion

New active materials for advanced performance (Li ion generations 3a and 3b).

- Silicon based anodes

- High safety & high voltage cathodes

- New electrolyte additives

- New separators and cell components

Our specialization covers from powder to power, which means from primary electrode materials to full size, application ready battery packs. As our motto goes, we aim to bridge the gap between research and industry. This means that we concentrate in knowledge generation and how to translate it into technology that can be smoothly transferred to the industry.

We develop new battery technologies starting from its fundamental materials and components, to make performing batteries with electrode formulations optimized for specific purposes and applications.

New active materials for advanced performance (Li ion generations 3a and 3b).

Two different high energy density cell technologies:

Activities focused on the development of:

After the basic development is achieved at lab level, the next step in our process is going an step forward through our fully equiped Battery Manufacturing Pilot Line.

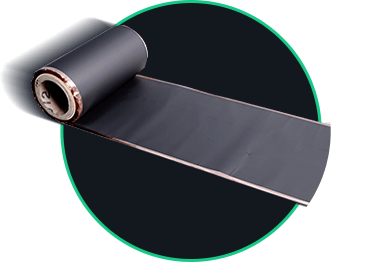

First, the scale up mixing, coating and calendering processes is performed according to industry state of the art techniques to produce continuous, double side coated professional electrodes.

In a second step we assemble fully performant battery cells up to 40Ah for validation and assessment of materials and processes.

Upscaling electrode formulations and process parameters.

Validation in product-like electrode & cell formats.

Specialists in water processing of electrode formulations.

Starting from any kind of format, size, shape or chemistry, we design, build and validate modules and battery packs.

We can taylor our designs to any specific application. just tell us your specifications.

From customer concept and specifications, we develop a fully functional battery pack ready for industrialization. Compliance with regulations and standards.

Design and development of control platforms that constitute the BMS architecture (HW). Implementation of functionalities and algorithms (SW) following the criteria established in the ISO26262 standard.

Mechanical design and development of modules and Battery Packs that guarantee the integrity of the battery and maximize energy density, taylored to the specifications of each application.

Design and development of thermal management systems based on different strategies:

We test advanced batteries of all sizes from coin cells to full size battery packs. Each type of battery –in terms of chemistry, size, purpose or application- deserves a taylored testing programme according to the specific needs. Find below the different options in our portfolio

Post mortem analysis allows us the identification of the failure modes of the batteries and in-depth understanding on cell degradation mechanism.

Results

As integral part of our battery materials and technology development, we assemble and test small coin and pouch cells for and early technology validation.

All kind of test, based on normalized test and on our own methodology, to extract knowledge about the behavior of the cells.

The results are used to develop models and State-of-Battery algorithms for BMS implementation.

Performance testing and validation of battery modules, usually developed from within our own research activities and partnerships.

Testing and validation of full size battery packs, most commonly from our own pack development & prototyping activities.

A key tool for undestanding, prediction and optimised design from battery cells to system level.

APROACH

High efficiency multiphysic models capable of predicting cell performance and lifetime. These models coupled with advanced optimization tools are able to improve cell design and provide lifetime predictions.

RESULTS

APROACH

Models based on equivalent circuits to accurately simulate the electro-thermal behavior at battery level. These models are the basis of the algorithms we develop for the estimation of State-of-Battery at the BMS level.

RESULTS

APROACH

We develop different prediction tools applying stochastic algorithms on regression problematic. This knowledge is used for the optimization in the sizing of energy storage or in the estimation of the useful life of the battery depending on the use conditions (first or next lifes).

We implement Artificial Intelligence techniques (deep-learning) trained with multiphysic model simulations for cell design optimization and lifetime prediction.

RESULTS

Full engineering capabilities from the cell to module/pack allow us to cover from demonstration to real life size battery packs, according to our customers specifications.

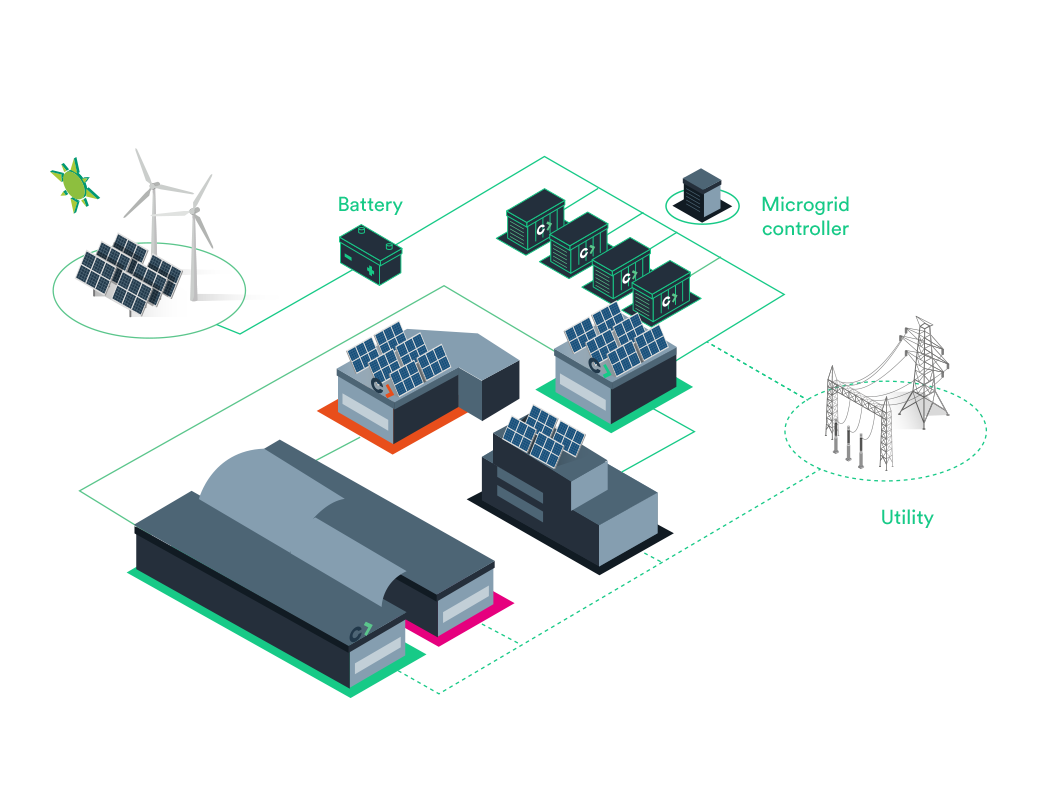

System sizing

Systems integration

Energy management system

At CIDETEC Energy Storage we develop full size battery pack solutions for electric buses and other heavy duty applications.

Our assignment corees from inicial cell choice and validation to full battery pack design, including BMS, communications and safety.

We build fully operative prototipes in close contact with our customer, so that at the end of the process we smoothly transfer a pack design already co-developed and validated together. Since the first vehicles started real operation at our home city Donostia-San Sebastian, many others units from several eBus models are hitting the European roads.