Anodic and cathodic active materials are mixed with the conductive carbon and binders in agreement with the quantities and procedures previously optimised on laboratory scale.

Our goal is to focus on aqueous based slurries in order to produce electrodes by low-cost and environmentally friendly procedures.

Waterborne cathodic and anodic slurries are prepared by mechanical stirring using two planetary mixers in order to avoid the cross contamination.

Temperature and vacuum level can be controlled depending on the requirements on the fabrication procedures.

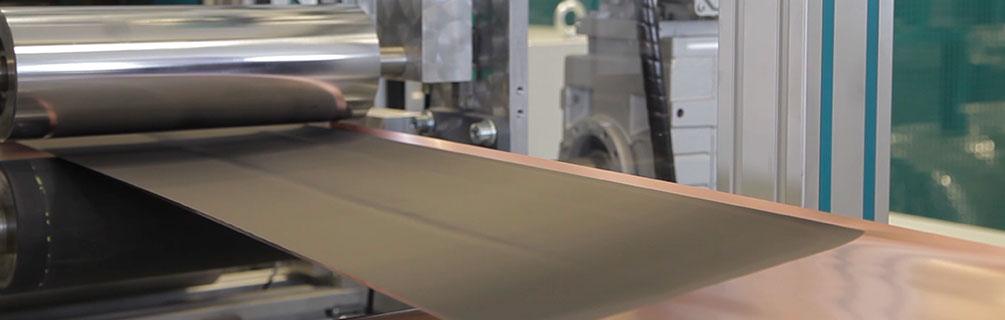

Knife, slot die and commar bar that will be selected depending on the desired properties on the electrodes. Drying zone is divided in 3 zones (1m long each) where the temperature and the air flow can be controlled. Dried electrodes are deeply analysed in order to guarantee the homogeneity in thickness and mass loading wide and lengthwise.

The coater has special filters and sensors to be able to coat organic based slurries.

The density of the electrodes plays a key role in the electrochemical performance. In order to reach the suitable porosity, electrode rolls are compressed by passing through a continuous calender.

Cutting of the electrodes is automatically performed by an electrode cutting die with the required dimensions where usually anodes are slightly larger than cathodes. Each cut electrode is checked by online quality monitoring with an accuracy of 100 micron or less of tolerance.

Stacking winding machine operates by automatic handling and alignment of the electrodes, with a tolerance of micron scale using a hot pressing lamination step.

The automatic assembled stacks can comprise the suitable number of electrodes to obtain the targeted capacity (from 10 to 50 Ah).